The RY4030 CNC slotting machine uses a manual scraping process, which can achieve micron-level precision control. With his keen sense of touch and years of accumulated experience, the master performs fine scraping on key components such as machine tool guide rails and work tables. Unlike the fixed mode of machine processing, manual operation can correct each subtle error point to ensure that the straightness and flatness of the guide surface are nearly perfect. This high-precision surface quality makes the cooperation of various components of the machine tool more tight and stable during operation, greatly reduces motion errors, effectively improves the dimensional accuracy and surface finish of the slotting process, and provides a solid guarantee for the processing of precision parts.

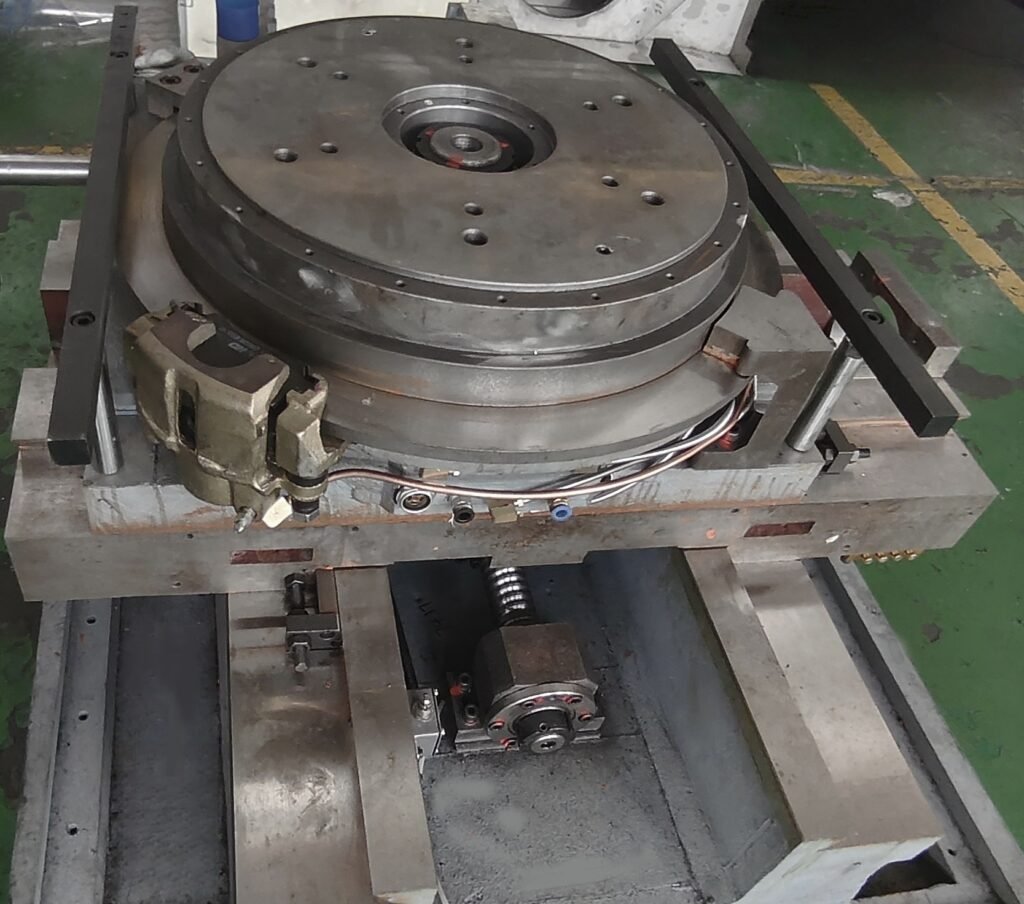

The base indexing head adopts intelligent brake function to achieve heavy cutting indexing without displacement, and automatically loosens and tightens during indexing, which is more stable. The lower end of the machine tool adopts an integrated bed and heavy-duty dovetail guide rails to improve the speed and rigidity of processing ultra-wide keyways and improve processing efficiency